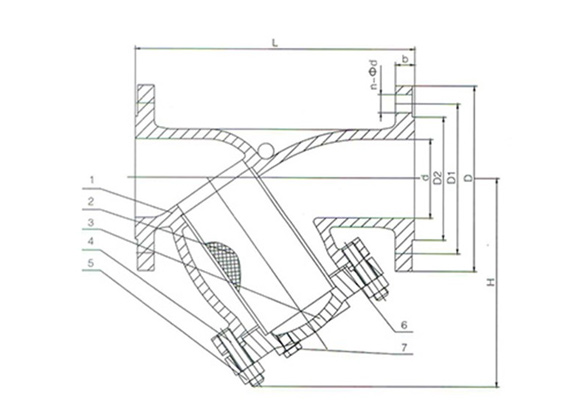

Appropriate inlet and outlet diameter

The inlet and outlet diameter of the Flanged Y Type Strainer must not be smaller than the corresponding inlet diameter and it is generally the best to be consistent with the inlet pipe diameter.

Casting material of Flanged Y Type Strainer

Different materials have different physical and chemical properties. The material of the Flanged Y Type Strainer you choose should generally be the same as the material of the process pipe connected to it. For different working conditions, you can specifically choose a Flanged Y Type Strainer made of cast iron, low-alloy steel, carbon steel, or stainless steel.

Selection of the number of mesh holes

The core working mechanism of the Flanged Y Type Strainer is the screen. Therefore, when choosing a Y-type filter, special consideration should be given to the size and number of holes of the filter screen that intercepts impurities.

EN

EN

Call us on:

Call us on:  Email Us:

Email Us:  No.68 Hezuo Road, Shijiazhuang City, Hebei Province, China

No.68 Hezuo Road, Shijiazhuang City, Hebei Province, China