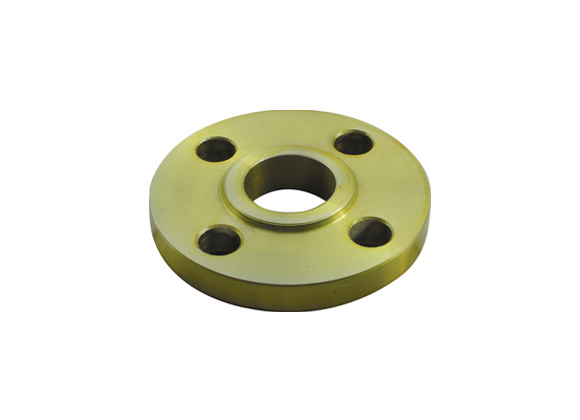

The main features of flange connection are easy disassembly, high strength, and good sealing performance. During the installing, the two flanges are required to be parallel, the sealing surface of the flange should not be damaged and it should be cleaned.

EN

EN

Call us on:

Call us on:  Email Us:

Email Us:  No.68 Hezuo Road, Shijiazhuang City, Hebei Province, China

No.68 Hezuo Road, Shijiazhuang City, Hebei Province, China