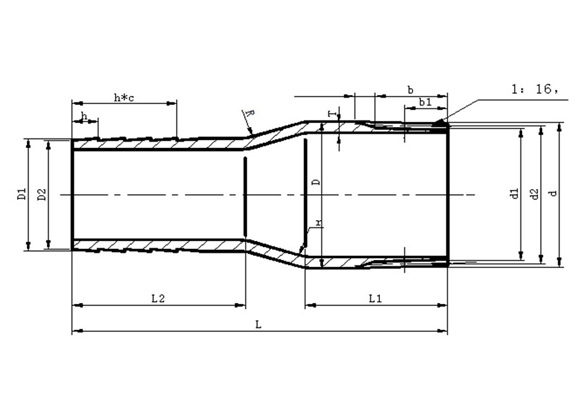

A King Nipple, also known as KC Nipple, is hose nipple fitting made from seamless steel pipe to connect hose. The King nipple makes the connection of the hose easier and the dis-assembly and replacement easier, which saves the cost of the hose connection greatly.

EN

EN

Call us on:

Call us on:  Email Us:

Email Us:  No.68 Hezuo Road, Shijiazhuang City, Hebei Province, China

No.68 Hezuo Road, Shijiazhuang City, Hebei Province, China