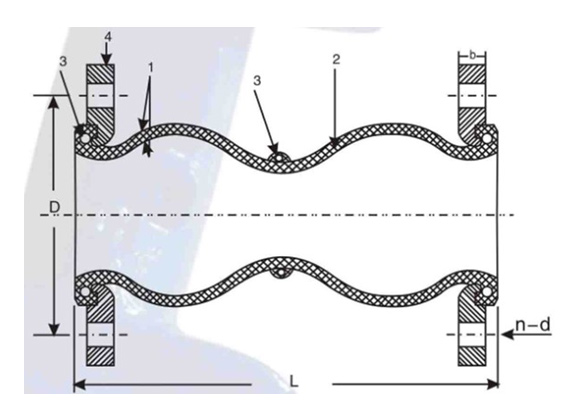

Both of them could absorb vibration and noise in the pipelines. However, twin sphere expansion joints could provide more pipeline motion absorption capacity, and even higher noise and vibration control efficiency. Furthermore, twin sphere expansion joints can withstand the most stringent pipe system configuration. They could provide better axial compression or extension, lateral deflection and angular motion.

EN

EN

Call us on:

Call us on:  Email Us:

Email Us:  No.68 Hezuo Road, Shijiazhuang City, Hebei Province, China

No.68 Hezuo Road, Shijiazhuang City, Hebei Province, China